- Producing high quality cooking and heating appliances – induction, electric, gas

- Series manufacture of metal parts with a high level of vertical integration: laser-cut, stamped, bent, drawn, welded and milled parts

- Manufacturing system components

- Using the right testing technologies to ensure our high quality standards

- Manufacturing production equipment that is adapted to suit the product and meet the customer’s requirements

- Industrialisation of small to high quantities, in line with the product and customer requirements

- Developing, designing and manufacturing working systems with in-house capabilities

Through the production of cooktops and metal components

With a high level of vertical integration

Want to have high quality products created with the latest technologies regardless of the number of pieces, flexibly, quickly and ecologically?

Our strengths lie in developing made-to-measure production systems and implementing the corresponding testing technologies to ensure our high quality standards. In this way we can guarantee you modern and efficient production methods and therefore fast delivery times. Our in-house toolmaking is available to make your project lead time even shorter. We can therefore produce all of the tools, fixtures and gauges to be used in production for you extremely promptly.

Key competencies Production

Production technology at GWM

We offer the following processing methods for the manufacture of your products:

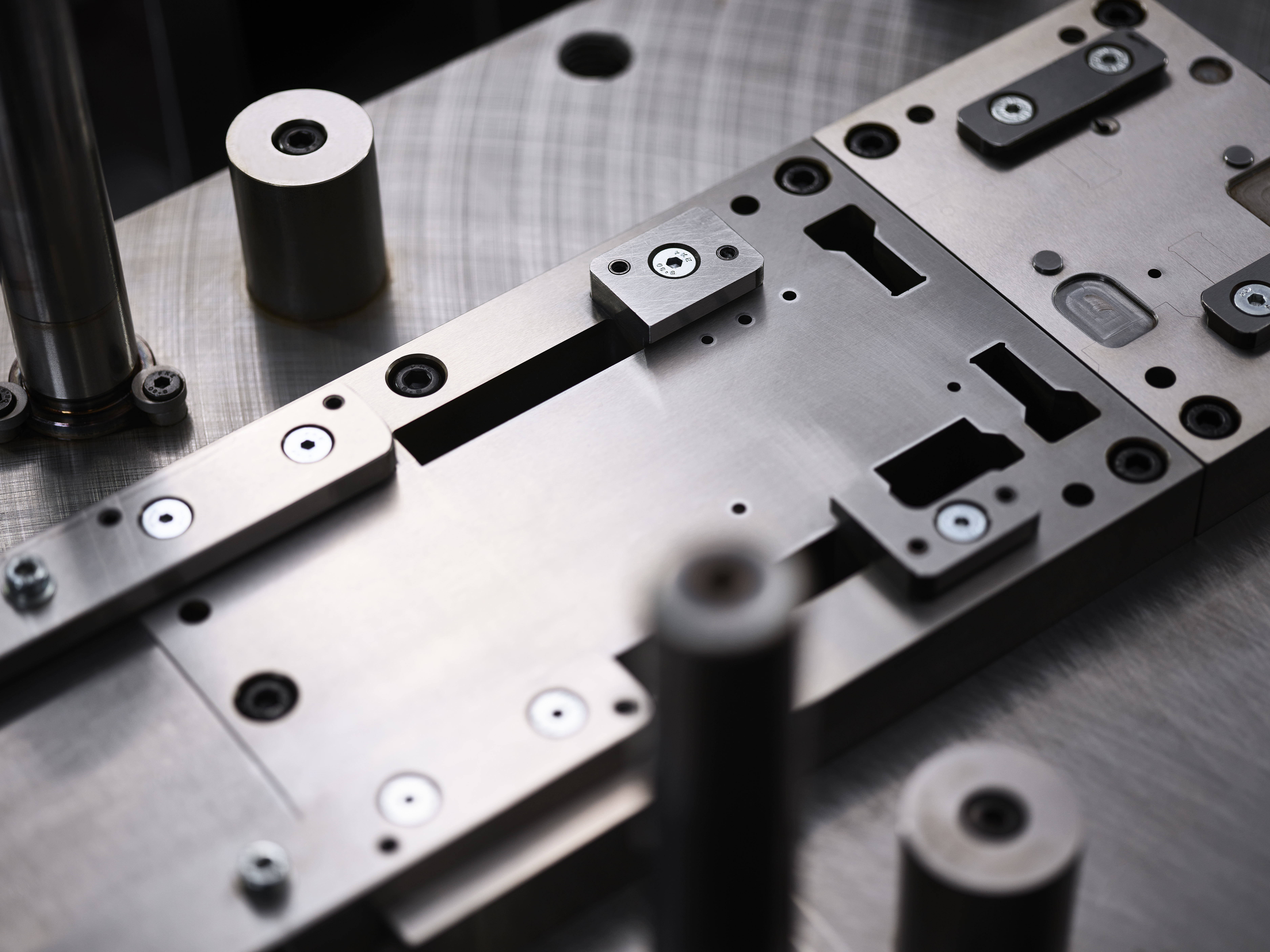

In-house toolmaking

We manufacture production systems, tools and fixtures for the industrialisation of your product.

We make customised tools in the thin sheet range, such as stamping, bending, drawing and progressive tools. Our production technologies range from 3-axis milling work, through surface and profile grinding, to wire cutting. Because we are passionate about tools, we can achieve shorter throughput times, high precision and quality, and low costs.

Any questions or concerns?

Then please don’t hesitate to contact us. We will be happy to advise you!